CESC Limited is one of India's oldest and most trusted power utilities, delivering uninterrupted and affordable electricity to millions across Eastern India. Backed by over a century of engineering excellence, CESC continues to modernize its generation portfolio while maintaining strong commitments to sustainability, safety, and digital innovation.

We are committed to generating uninterrupted power for our consumers while maximizing capacity utilization through cost-effective and efficient operations. Driven by innovation, we continuously improve performance and integrate safe, reliable, and environmentally responsible practices into our operations and maintenance, aligned with ESG principles and our core corporate values. Our operations are supported by four coal-fired power generating stations with a combined installed capacity of 2,125 MW.

Pic- Budge Budge Generating Station

Our plants are certified to ISO 9001, ISO 14001, ISO 45001, ISO 50001 and ISO 27001, reflecting our commitment to quality, environmental stewardship, occupational health and safety, and energy management. Through a zero-incident safety culture and continuous improvement initiatives such as KAIZEN and 5S, we strive for operational excellence and a consistently safe workplace.

Pic- Southern Generating Station

The first commercial Thermal Power Station of 1000 kW capacity in India was commissioned by CESC on 17th April, 1899 at Emambagh Lane (Now Prinsep Street) by Colonel REB Crompton, then President of IEE. The plant was equipped with 'Crompton' Dynamos, 'Willans' engine and 'Babcock & Wilcox' Boilers. This earned Colonel Crompton the name as the father of first thermal power plant in India.

Then 15 MW was commissioned at Cossipore, North Kolkata on 20 July 1912. Capacity additions continued through 1912, 1925, and up to 1932, when the station reached 96 MW. To meet southern Kolkata's demand, the Southern Generating Station at Metiabruz was commissioned on 22 December 1926 with 22.5 MW, later expanded to 70 MW.

In 1940, the Mulajore Generating Station was set up in North Kolkata with two 30 MW units, eventually expanding to 150 MW by 1951. Post-World War II industrial growth led to the commissioning of the New Cossipore Generating Station in 1949, starting with 110 MW and later expanded to 160 MW in 1963. The original Cossipore station was closed in 1978 due to aging.

During power shortages in the 1970s, expansion was limited by regulations, which eased in the early 1980s. This enabled commissioning of the 240 MW Titagarh Thermal Power Station (four 60 MW units) between 1983-1985. In 1990-91, the old Southern Station was replaced by a modern plant with two 67.5 MW units.

Between 1989-1997, CESC operated the Kasba Gas Turbine Station (2 x 20 MW) on lease. The company’s largest and newest plant, the Budge Budge Generating Station, was commissioned between 1997-1999 with 500 MW, and expanded to 750 MW in 2010. Due to aging, the Mulajore and New Cossipore stations have since been retired.

Haldia Energy Limited, a group company of the flagship RP-Sanjiv Goenka Group, developed a 2X300 MW Thermal Power Plant at Haldia, West Bengal to cater the growing power demand of the city of Kolkata and its suburbs.

Pic- Haldia Energy Limited

Dhariwal Infrastructure Limited, a 2 X 300 MW coal based thermal power plant, located in the state of Maharashtra is a wholly owned subsidiary of CESC Limited, flagship power utility of RP-Sanjiv Goenka (RP-SG) Group of companies.

Pic- Dhariwal Infrastructure Limited

Crescent Power Limited- 40 MW

CPL operates a coal washery and a thermal plant near Asansol in West Bengal. The washery cleans the coal mined at the ICML, which is then transported to the power generating plants of CESC. The rejected coal is sent to the adjacent power plant, which produces environment-friendly power and promotes zero wastage.

Pic- Crescent Power Limited

In the mechanism of the power generation process, the key focus areas are

The most important objective of our power generation process is to provide uninterrupted power supply to our consumers at a competitive price. Availability & Reliability of a power plant with efficient operation is our key objective.

CESC is always striving hard to generate electricity with optimum use of fossil fuel & reduction in Green House Gases.

CESC climate change mitigation strategy for the generation business focuses on Auxiliary Power Management, Process Efficiency and Optimization, GHG and Air Emissions Accounting, and Cleaner Energy Transition through increased Renewable Energy Capabilities and Fuel Diversification.

CESC has actively gone for adoption of the best international practices for protection of the environment & associated biodiversity. The success of environmental control measures can only be ascertained by proper monitoring and control of the environmental parameters beyond the normative.

Various facets of environment management like waste and effluent management, emission control, concern for climate change, biodiversity protection and promoting awareness are proactive focus areas.

In its constant endeavour to protect and preserve ecological goods and services through judicious use, CESC ensures compliance to applicable environmental regulations in India and de risks its operations from potential risks through a sound Environmental Management System. These processes are periodically audited internally, by external certification bodies and local regulatory authorities

At CESC Water is being managed responsibly across generation operations through efficiency improvement, recycling, and zero liquid discharge (ZLD) practices. During the year, average specific water consumption remained below industry and national benchmarks, with ZLD achieved at three thermal plants. Multiple conservation initiatives - including process optimisation, large scale rainwater harvesting, nature based restoration, 100% of treated water utilization through advanced treatment systems - strengthen long term water security and resilience.

CESC is committed to protecting and enhancing Biodiversity Conservation across its generation operations with a strong focus on creating net positive ecological impact. The Company has developed urban forests with Miyawaki Technique, biodiversity parks, medicinal and butterfly gardens using native species to support pollinators and local ecosystems. Through expanded green belts and community engaged conservation, CESC integrates biodiversity protection into responsible and future ready operations.

CESC follows a circular approach to Waste Management across its generation operations, covering both hazardous and non hazardous waste streams such as ash, e waste, plastics, metals, and C&D waste. Robust systems for waste segregation, labelling, storage, documentation, and disposal through authorised agencies ensure regulatory compliance and minimal landfill dependency. The Company embeds the 3R principle by refurbishing equipment, reclaiming mineral oil, converting organic waste into compost and biogas, and managing fly ash and bottom ash for productive reuse, including patented applications in construction. Through continuous monitoring and innovation, CESC is progressing towards zero waste to landfill while strengthening resource efficiency and environmental responsibility.

The CESC has obtained Green Building Certifications and adopted sustainable design principles to use resources more efficiently and reduce its environmental footprint, Eco friendly practices are embedded throughout the lifecycle of its offices and facilities - from construction to day to day maintenance - supporting energy efficiency and ongoing efforts to lower carbon emissions. We are steadily increasing the use of electric vehicles (EVs) across our sites.

CESC has taken 4 no's Key Initiatives for Integrating of all function for better Operational Excellence:

Project Sankalp: Project was taken by CESC for improvement of Operational Efficiency through Cross Functional Team (CFT) Like Heat Rate, APC, DM water, Sp Oil Consumption. This helps for reduction of various losses & improve Energy Efficiency.

Param Sankalp: is a 6 Year Rolling Plan to decide unit running strategy based on Run, Repair & replace.

This will help to decide 1. Fit to Service 2. Fit for Service 3. Fit ever Service.

Project "SAMARTH" under ACOE was launched to drive Analytics driven solution and models that will help in reducing losses and improving Operational performance, efficiency, reliability and sustainability of a thermal power plant. ACOE (Analytics Centre of Excellence) has been established to drive analytics driven solution in the organisation.

A Community of Interest (COI) is the Initiative that are taking to create a common platform "Saksham" for knowledge sharing, expert advice and solutions in troubleshooting, root cause analysis and best practices, to resolve any technical issue timely and bring back equipment & unit earliest to improve unit loading and availability.

Safety and employee well-being are fundamental to our operations. We are dedicated to cultivating a strong, interdependent safety culture where every individual actively takes ownership of workplace safety. Guided by our Safety Policy and aligned with ISO 45001 standards, we maintain a robust Occupational Health Management system supported by comprehensive documentation and round-the-clock medical services.

Our plants are certified to ISO 9001, ISO 14001, ISO 45001, and ISO 50001, reflecting our commitment to quality, environmental stewardship, occupational health and safety, and energy management. Through a zero-incident safety culture and continuous improvement initiatives such as KAIZEN and 5S, we strive for operational excellence and a consistently safe workplace.

Budge Budge Generating Station (BBGS)- 3x250 MW

Southern Generating Stations (SGS)- 2x67.5 MW

Haldia Energy Limited (HEL), 2 X 300 MW

Dhariwal Infrastructure limited (DIL) - Chandrapur, 2 X 300 MW

Environmental Responsibility & Sustainability

CESC is committed to responsible power generation by going beyond statutory compliance and voluntarily adopting clean, sustainable technologies in line with the Charter of Corporate Responsibility for Environment Protection (CREP)

Our generating stations consistently meet and exceed prescribed environmental targets through continuous innovation and rigorous monitoring.

We deploy advanced emission control systems, including high-efficiency Electrostatic Precipitators, Wet ESPs, low-NOx burners, flue gas conditioning, and real-time online emission monitoring with direct data transmission to regulatory authorities. Our initiatives have significantly reduced particulate matter, NOx, SOx, and greenhouse gas emissions, making CESC the first thermal power utility globally to be registered with UNFCCC for Carbon Credits, with two registered CDM projects.

Water stewardship is a core focus. All our generating stations operate total effluent recycling and zero-discharge systems, supported by advanced effluent treatment, cooling towers, root-zone sewage treatment, and water conservation practices. Fly ash is handled through dry ash systems with 100% utilization, supporting construction and cement industries while eliminating ash pond dependency.

We ensure responsible management of hazardous, biomedical, and e-waste through authorized recyclers and disposal facilities, alongside continuous ambient and work-zone air quality monitoring. Extensive green-belt development, large-scale plantation drives, and biodiversity initiatives further reinforce our environmental commitment.

Our Environmental and Occupational Health & Safety Management Systems are ISO 14001 and ISO 45001 certified, overseen by a dedicated corporate Environment Cell and specialized task teams. These sustained efforts have earned CESC numerous national and international awards for excellence in environmental performance, water stewardship, ash utilization, and clean power generation.

Budge Budge Generating Station (BBGS)- 3x250 MW

Southern Generating Stations (SGS)- 2x67.5 MW

CESC -Budge Budge Received Global Sustainability Award

Haldia Energy Limited (HEL) has been honored with the prestigious "Best Sustainability Initiative of the Year Award - 2025" at the Global CSR and ESG National Conference

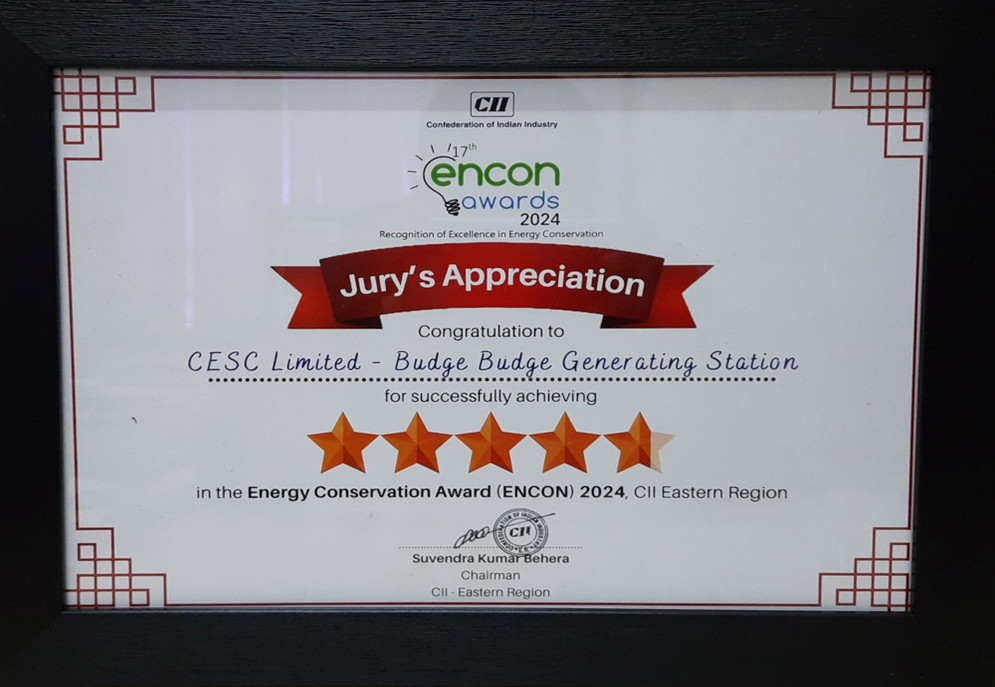

CII 26th National Award for Excellence in Energy Management 2025

CESC Budge Budge received Environment Excellence Award

CESC Southern Generating Station Received Gold Award in Environment Excellence